The Cost of Measurement Error : Why Insize Measuring Instruments are the Standard for Indian Industry

The part looked perfect. It had just come off the machine; the dimensions appeared correct, and the surface finish was clean. Everything seemed ready for assembly. But during installation, something didn’t fit.

At first, the issue wasn’t obvious. The machining process was correct, the operator was experienced, and the machine was calibrated. Yet the assembly failed. This is a situation workshops and manufacturing facilities encounter more often than they expect. The real problem isn’t always machining—it’s measurement.

Why Accurate Measurement Is the Foundation of Manufacturing

In any workshop or industrial environment, machining is only one part of the process; verification is equally critical. Even a deviation of 0.02 mm can cause:

● Assembly failures

● Excessive wear and mechanical vibration

● Reduced equipment lifespan

● Unexpected operational failure

Precision measuring instruments determine whether a component truly meets its required tolerances or only appears to. This is why workshops, tool rooms, and industrial quality control departments rely on trusted brands like Insize measuring instruments to ensure dimensional accuracy before assembly.

Essential Insize Workshop Tools for Precision Quality Control

Different applications require different measuring tools, each serving a specific purpose.

1. Insize Vernier Calipers

Among the most widely used tools in workshops. These are essential for measuring external and internal dimensions as well as depth. They provide the versatility and accuracy needed by machinists and technicians.

2. Insize Micrometers

When higher precision is required—such as measuring shaft diameters or the thickness of precision machined parts—micrometers are the preferred choice. They provide higher accuracy compared to vernier calipers.

3. Dial Indicators and Height Gauges

● Dial Indicators: Used to detect small variations in surface alignment, machine setup, and runout measurement.

● Height Gauges: Essential for measuring vertical dimensions and marking reference points in inspection departments and quality control environments.

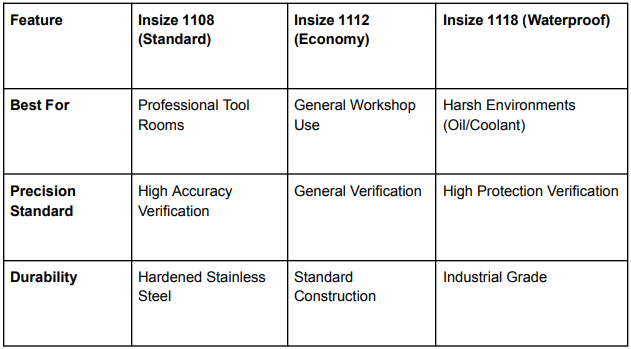

Comparison: Choosing the Right Insize Digital Caliper

The Role of Measuring Instruments in Modern Industry

Modern machinery operates with tighter tolerances than ever before. As machines become more advanced, even small dimensional deviations can cause performance issues. Using reliable measuring instruments improves workshop efficiency by:

● Reducing Rework: Identifying errors early in the process.

● Improving Consistency: Ensuring every component meets required specifications.

● Increasing Confidence: Providing technicians with reliable data.

Why Workshops and Industries Trust T Saifuddin & Co for Insize

Access to genuine measuring instruments is essential for maintaining accuracy and reliability. T Saifuddin supplies Insize measuring instruments to workshops, tool rooms, and industrial facilities across India.

Professionals trust T Saifuddin because they provide:

● Genuine Insize measuring instruments.

● A wide range of precision measuring tools.

● Reliable product availability and support for industrial requirements.

Conclusion: Measurement Determines Quality

Machining creates the component, but measurement verifies its accuracy. Without precise measurement, even perfectly machined components can fail. Workshops and industries that prioritize accurate measurement—particularly through the use of Insize measuring instruments—achieve better results, reduce failures, and maintain higher quality standards.

Upgrade Your Quality Control Today

Don’t let measurement errors impact your production. Contact T. Saifuddin and Co to explore our full range of Insize precision tools and secure a bulk quote for your facility.